While we may think of an item straight off the production line as sterile, it can actually come into contact with numerous contaminants. To ensure the end product is safe for use, a series of proper sanitation steps must be followed. One such step that is especially critical in the medical device manufacturing industry is bioburden testing. Below is a brief look into what this assessment entails and why it is a key component in the sterilization process.

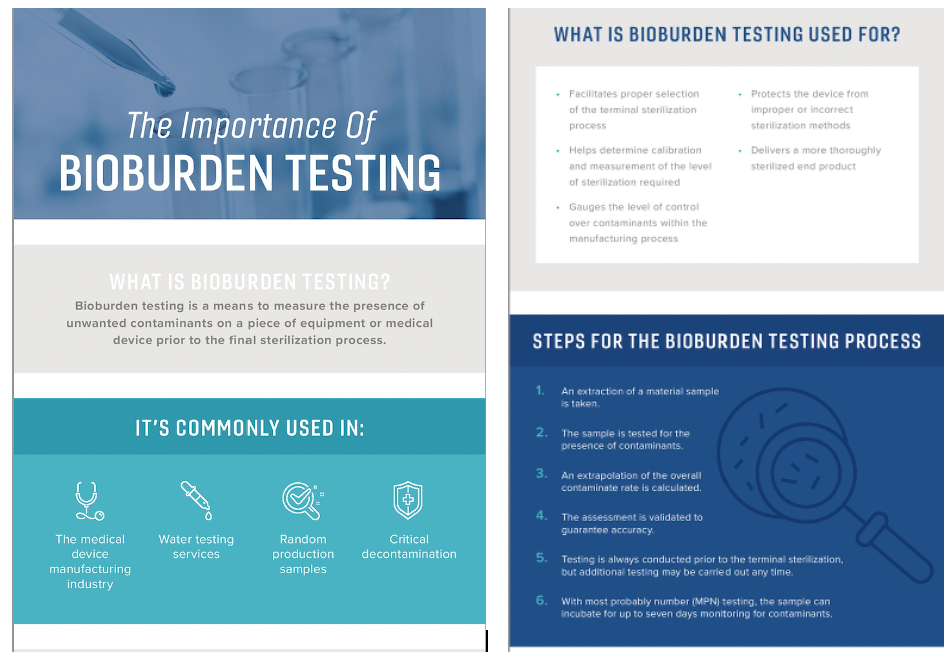

To start with, what is bioburden testing? Simply put, it is a method of measuring the contaminants present before the final sterilization process of a device, component or other manufactured good. Most frequently, the types of contaminants being tested for are microorganisms. These could include aerobic bacteria, anaerobic bacteria, spores and fungi, to name a few.

What makes bioburden testing so important? When a patient receives a medical device, it must be properly sanitized. Otherwise, it risks introducing harmful contaminants, such as the microbes above, to the patient. As many of the recipients suffer from compromised health or are otherwise vulnerable, such contamination could result in a serious infection or may even be fatal. Thus, proper sterilization is paramount.

Bioburden testing works to ensure final sterilization is optimal. How so? With a reliable measurement of bioburden, a more accurate and effective process can be selected for sterilization. It also works to verify the correct calibration and level of sterilization required within that process. Without this step improper or incorrect techniques may be used and, consequently, the decontamination may prove to have been insufficient when the device is used or implanted.

The steps for the bioburden assessment process are straightforward. First, an extraction of a material sample is selected for testing. Next, measurements of the presence of specific contaminants are taken. Once these quantities (or lack thereof) are determined, an extrapolation of the overall contaminant rate is generated based upon that sample. This is the most effective approach; however, there is an alternative method known as most probable number (MPN) testing. MPN involves monitoring the sample for growth or non-growth of contaminants over a seven-day incubation period.

The final step of the process is critical. It pertains to validating the testing method and sample results. It involves introducing a small, predetermined quantity of a specific micro-organism into the sample. Then, the test results are compared and validated against this known number. Such validation works to guarantee accuracy of the testing method. It also functions as a means to determine that the test was a non-destructive process and future readings are accurate.

For further information on the bioburden testing process and its importance, please see the accompanying resource by Technical Safety Services.